Spark Plugs

As the main source of power in any petrol engine, a spark plug performs anessential function: It is responsible for igniting the air-fuel mixture in thecombustion chamber of petrol engines. This combustion process creates power,which sets the vehicle in motion. To make sure this process runs smoothly, thespark delivered by the spark plug must ignite just before the piston reaches its highest point and the compression is at its greatest.

Read More

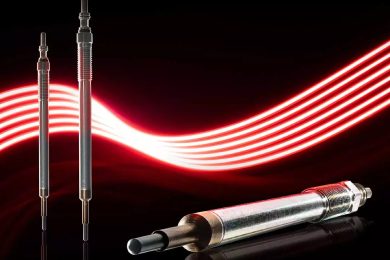

Glow Plugs

NGK glow plugs are setting new standards in glow plug technology. Under a certain temperature, the engine will not start without well-performing glow plugs. Therefore, glow plugs are mandatory to ensure a perfect engine start, especially in cold conditions. This is why Niterra is constantly expanding its expertise. Two glow plug types: metal rod glow plugs and ceramic glow plugs have special characteristics in regard to thermal behavior.

Read More

Ignition Leads and Caps

There are three requirements that top-notch NGK ignition leads need to fulfill: Firstly, outstanding insulating characteristics, secondly a high level of resistance and finally, resistance to vibrations and fluctuations in temperature and humidity. If the ignition leads meet these requirements they can offer permanent reliability under extreme conditions. NGK ignition leads are a key element in the ignition system of many petrol engines.

Read More

Ignition Coils

The ignition coil's design and material must be resistant to heat and moisture in the engine bay and function reliably. Oil and petrol vapours mustn’t be able to harm the housing: This damage to the housing would impair the function. NGK ignition coils use the technology car manufacturers require. The vacuum moulding process ensures a blister-free encapsulation. Each ignition coil is produced in strict compliance with OE specifications.

Read More

Oxygen/Lambda Sensors

With its NTK oxygen sensors launched in the 1980s, Niterra was among the pioneers in this field. Since then, the reduction of harmful emissions has made significant advances, not least thanks to the development of innovative technologies and extensive research. Today, highly efficient ceramic heaters in lambda sensors ensure, for example, that the sensors start measuring sooner and respond faster. To achieve more accurate measurements in order to meet the ever more stringent Euro standards, huge efforts are being made in the continuous improvement of the ceramic components.

Read More

Exhaust Gas Temperature Sensors

Temperature sensors use resistors whose resistance changes with temperature. Two different types of sensors : PTC and NTC. While wih Positive Temperature Coefficient resistance increases with rising temperature, with Negative Temperature Coefficient resistance decreases with rising temperature. NTC sensors are more accurate in measuring than PTC sensors; but as NTC sensors used to be sensitive on high temperatures, mostly PTC were used to measure exhaust gas temperature. These use temperature resistant elements that cover a range from -40°C up to 900°C.

Read More

MAP/MAF Sensors

The majority of MAF sensors come in two variations: hot-wire technology and hot-film technology. These MAF sensors have no moving parts and use electrical current to measure air mass. MAP sensors provide immediate data on the manifold/boost pressure to the ECU, measuring air pressure to make calculations for fuel, and ignition calibration, which is vital to maintain engine efficiency. The MAP sensor measures the air pressure by the deformation of a membrane with integrated resistors. The pressure varies depending on the throttle position, engine speed and turbo operation.

Read More

Exhaust Gas Recirculation Valves

There are three basic types of EGR valves. Pneumatic EGR valves have a vacuum controlled diaphragm. These valves can enable a higher flow rate that is required by newer diesel applications. Electric EGR valves are controlled through integrated electronics. These valves are run directly by the engine’s control unit and can be much more precisely regulated. And then there are electric EGR valves that have a cooling unit to further reduce the temperature of the exhaust gases. The new range has the same high quality like all the other products that Niterra are renowned for.

Read More

English

English  عربي

عربي

Français

Français